TCHN-BCHN Series Hydraulic Nuts

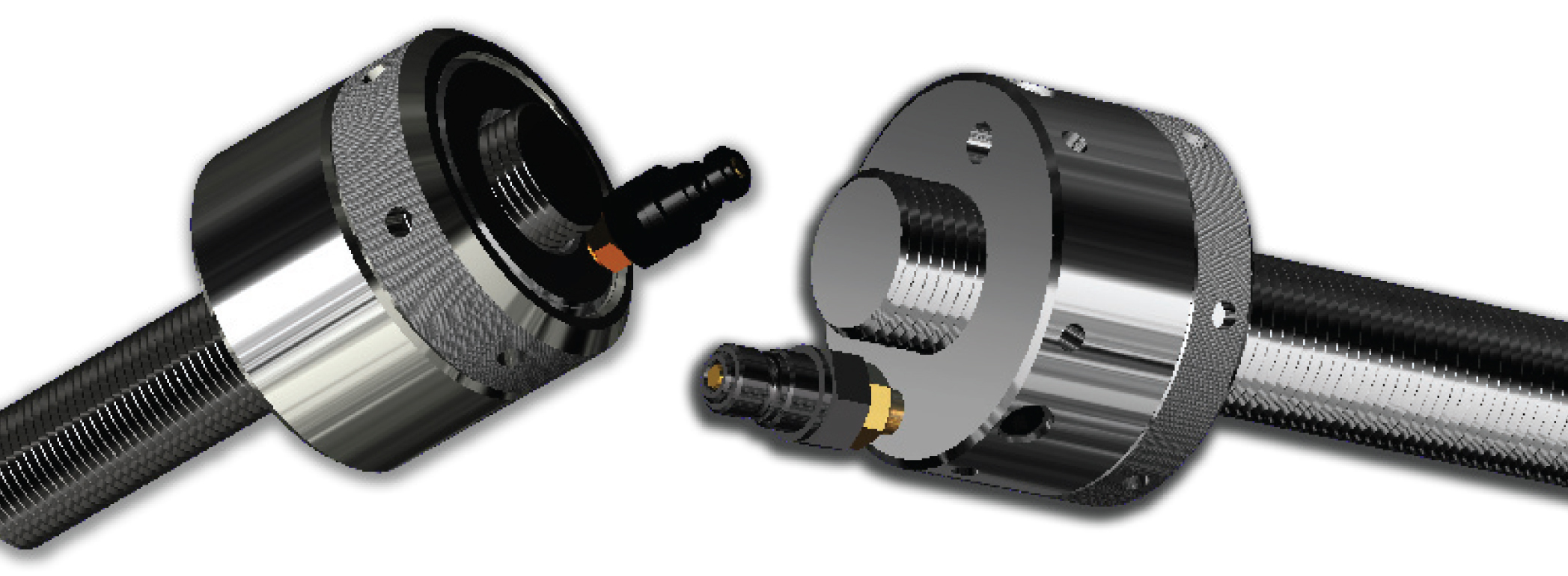

Series: Top Collar Type and Bottom Collar Type

These Nuts replace existing hexagon nuts to give a rapid, accurate and uniform bolt load to any bolted joint. The Nut offers a method of bolt tensioning multi-bolt applications which greatly improves the integrity of the joint. The speed in which joints can be tensioned and detensioned shows an extraordinary time savings over conventional detachable bolt tensioning systems. An existing oil company has recently reported a massive time saving of 1750% over their old bolt tensioning system, through the use of these hydraulic nuts.

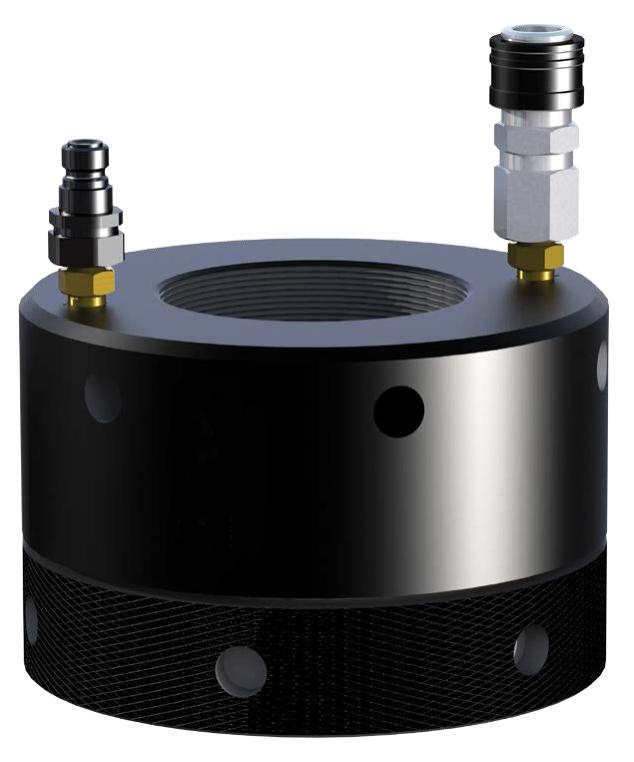

The Principle

Hydraulic pressure is applied simultaneously to each Nut. All frictional factors connected with conventional bolt tightening methods are alleviated since Nuts apply a direct axial force to the bolt which generates bolt elongation. This elongation/tension is permanently retained by means of the load retaining collar. The Nuts have been designed to be as compact as possible, allowing more nuts to fit on an application. In most cases they produce a residual bolt stress of 45000 lbs/In2 (310N/mm2), which is more than adequate for most bolted joint applications. As pressure is applied to the Nuts not only does the bolt elongate but also joint compression occurs. Since many applications incorporate some form of gasket, this joint compression can be substantial. In order to withstand this, all Nuts are capable of considerable piston movement. This allows the Nuts the ability to tension a complete joint in only one pressurization sequence, which can result in significant high time savings.

Main Features and Benefits

- Standard Hydraulic Nuts are suitable for use in temperatures up to 100oC. For temperatures above this level special seals are available, contact us for further details

- The use of machine cut polyurethane seals, ensures a reliable leak free Tensioning system

- These Nuts can be used with spherical washers where joint members are badly out of square

- Where the standard Nuts are not suitable, special designs are available on request. Ask us for all the possibilities.

Pressure

Use either a air driven pump unit or a hand operated pump unit to apply pressure to these Hydraulic Nuts.

Notes

MAXIMUM WORKING PRESSURE = 33000 PSI : 2275 BAR

IF THE STANDARD HYDRAULIC NUTS ARE NOT SUITABLE WE OFFER SPECIAL DESIGNS ON REQUEST.