We at BRAND TS have gained extensive experience and insight in the industry over the past 40 years. Our knowledge and experience is spread across a wide range of industries.

WELCOME TO BRAND TS

BRAND TS

TOOLS & EQUIPMENT FOR THE INDUSTRY

We supply special tools and equipment, provide advice, training and also rent out systems.

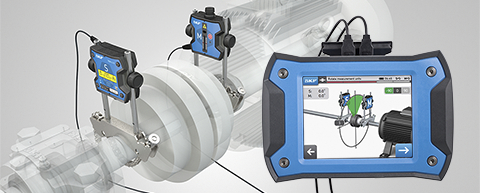

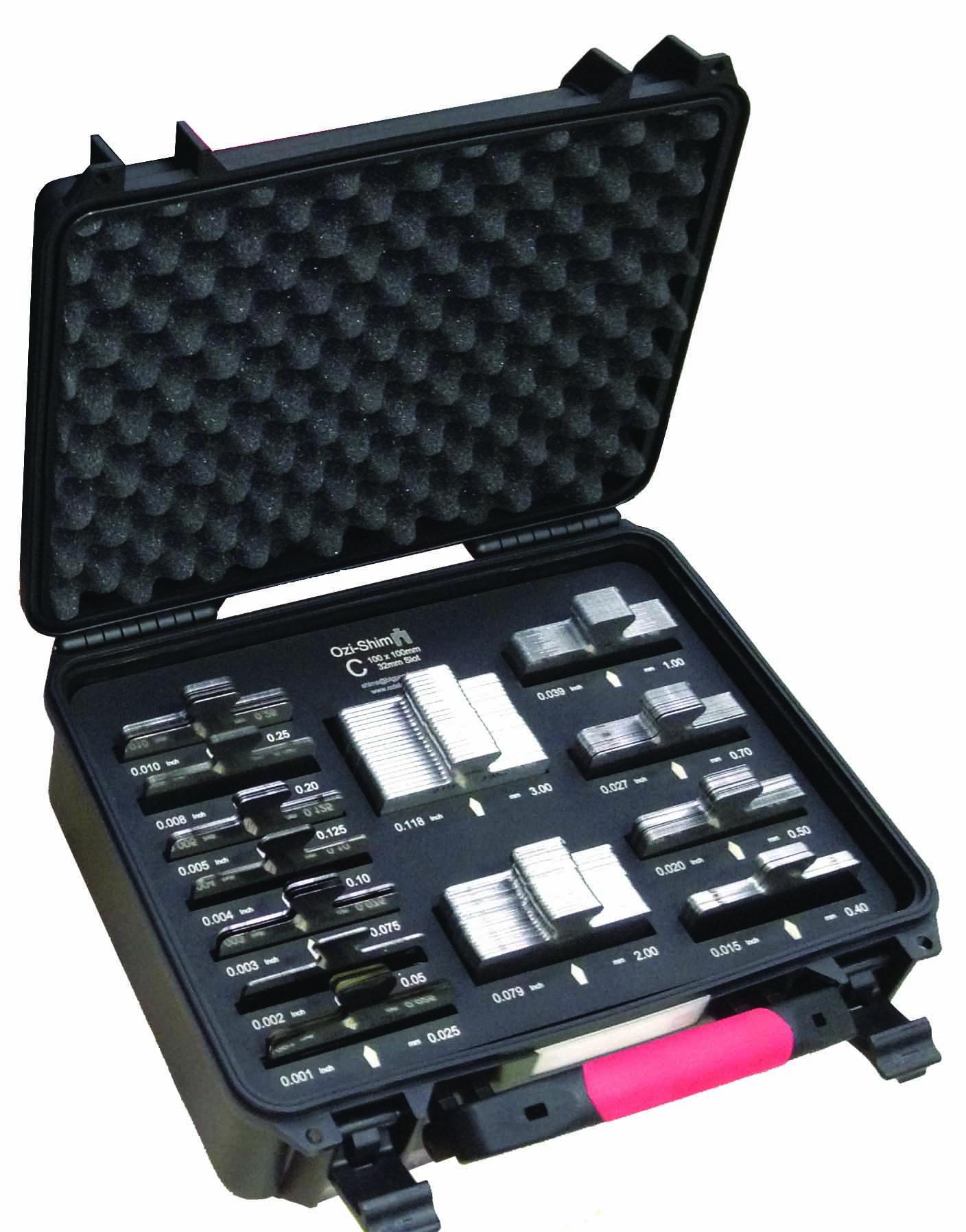

Laser measure and alignment systems

Among other things, like straightness, flatness, level, line bore centerline, flange measurement, parallelism, interferometry, digital machine level, shaft alignment, shims stainless steel plates, roller or cylinder profile measurement, pulley maintenance, 3 D scanning, line laser, cross laser and dot lasers.

Bolting Tools

Assembly - assembly tools from 0.3 nm up to what is required, even if it is 120,000 KN or more Such as hydraulic, air and electric battery or battery torque wrenches, Impack socket, hexagon reducers, backup wrenches, bolt tensioners, induction bolt heating systems, plate heat exchanger tightening tools, cylinder mounting tools and hydraulic nut splitters.

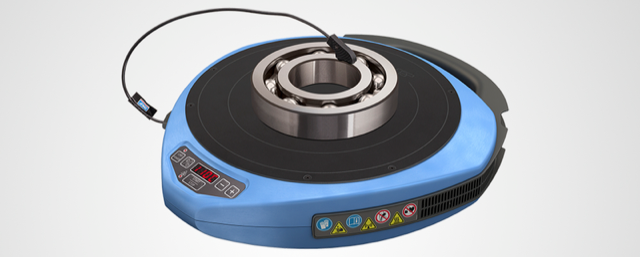

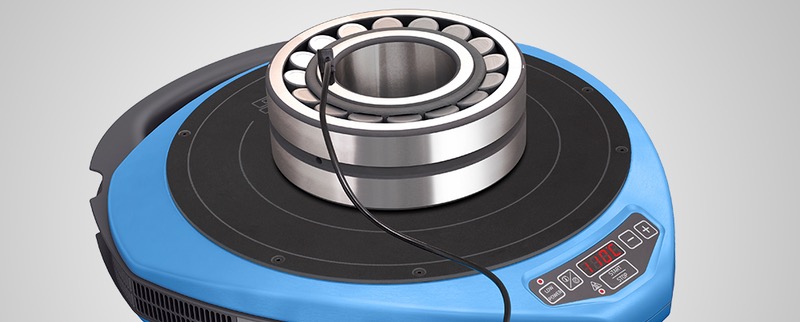

Induction Heating Equipment

There are various options for applying induction heating. Think of heating up bearings or gears. Heating up bolts with induction to extend the lenght so that it can be loosened or tightened. This is for large turbines or compressors. But also preheating, shrinking, straightening, annealing or melting with induction heating. There are several options, look further on this website.

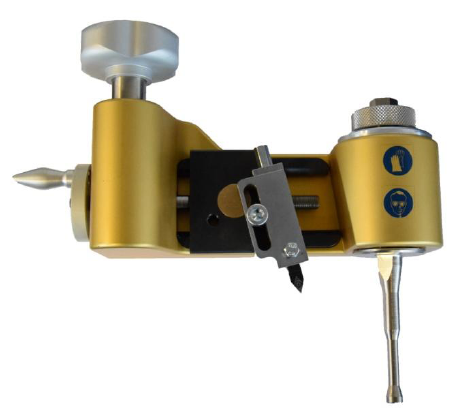

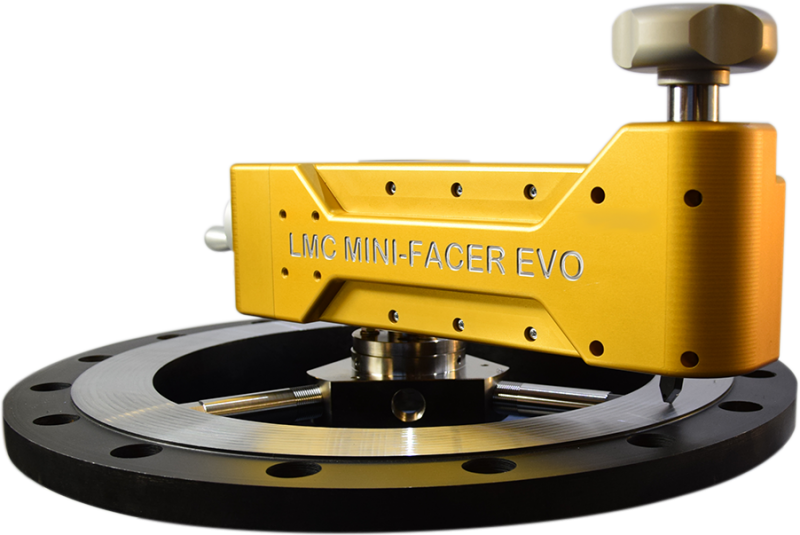

Onsite Machining Tools

Flange facer for small and big flanges, onsite milling, machining of tubes, tube relining, tube and pipe work, centerless circular grinding of rings and drums.

Cylinder Repair Bench

Cylinder disassembly assembly and repair bank There are several different types from just disassembling the piston rod nut or just pulling the cylinder apart to the whole process from disassembling to reassembling cylinders, but also testing up to 200, 300 or 500 Bar. The bench has the ability to loosen the nut to a force of up to 135,000 Nm, below the 135.000 Nm there are also other power options. There are various ways of screwing the nut onto the piston rod, from hex to round with 2, 3 or 4 holes on the outside or on the front, everything is (standard) possible. This is also possible to unscrew the cylinder if this is not with a normal bolt connection.