HELIOS 35 Induction bolt heating system

To rent or buy

Induction bolt heating tightening system with the HELIOS 35

When manufacturing machines that produce or use a great power, it is necessary to tighten and untighten bolting of big dimensions and high mechanic resistance.

The most common method concerns the heating of threatened pins by means of a long electric resistance called "candle" inserted into an hollow pin. Heating up hollow studbolts.

This method is frequently used in the tightening and following disassembly of steam turbine cases. The limits of heating by irradiation include a long time in performing the procedure and poor safety for workers. The workers must in fact handle the irradiating candle with high risks of burns.

The KERA 30 has a successor and that is the HELIOS 35

NEW FEATURES COMPARED TO PREVIOUS MODEL KERA 30.1

More powerful - Reduced heating time and optimized efficiency thanks to the power regulation function according to the inductor size and shape.

Easy to manage - 4.3” color graphic display with easy menu and guided startup procedure so as to immediately set and use the machine.

USB port - Allows to download/upload configurations, save the operating data and send them to our technical assistance service for analysis.

Customizable inductors - Customization is our business. According to specific requirements we produce a wide range of inductors, in terms of both dimensions and shape.

Optional Functions - Timer, Ring-Shaped Inductors and Connectivity.

Smart system - Faults detection system with automatic power shut-off in case of alarm.

Diagnostics - This machine is designed to communicate remotely through wifi and modem connections. Through this function, is possible to provide a predictive maintenance service.

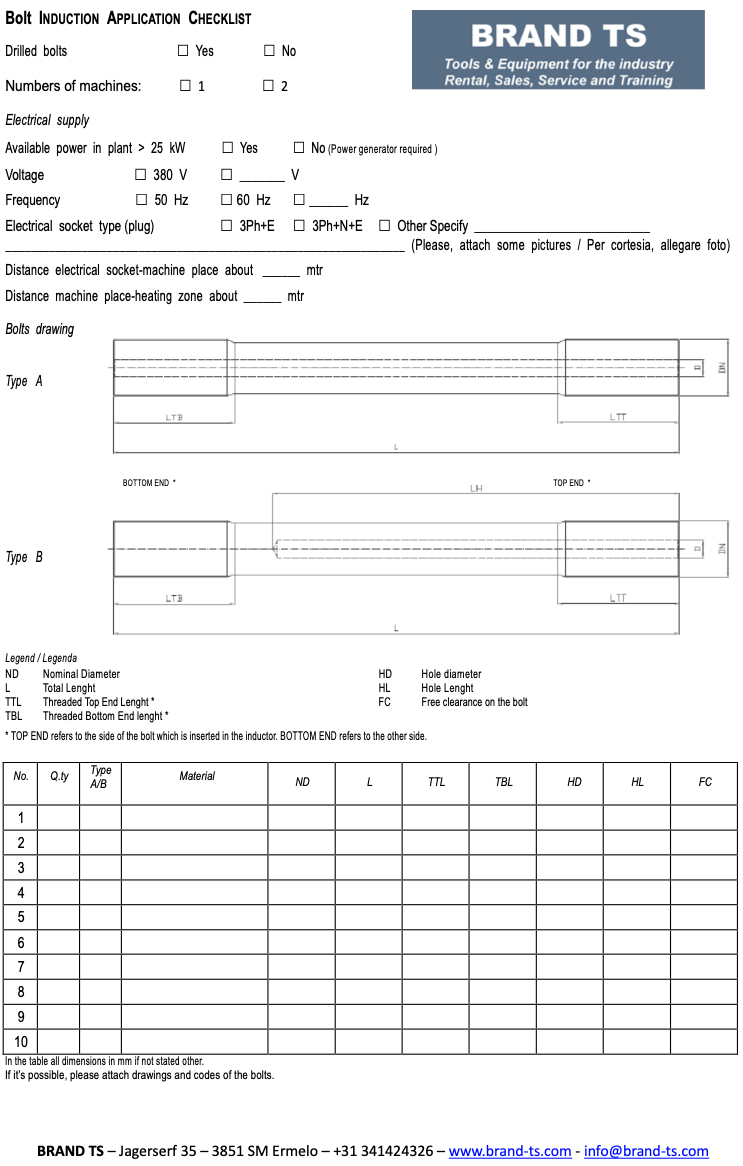

For tightening and loosening drilled bolts by magnetic induction heating

Main advantages of HELIOS 35 bolt induction machine (compared to traditional systems):

- Big saving in time (1:10 compared to traditional methods such as electric candles or flames!)

- Total safety for operators (inductors remain cold thanks to the intercooling system!)

- Easy to move and transport

- Set-up software very easy to use

- Fully automatic machine

- Only 1 day training to use the machine

- Automatic operation error detection

- Protection of machine: automatic stop in case of default

- Only one cable for High frequency cable and water cooling cable

Technical characteristics

- Inner intercooling system (no external water feed required)

- Automatic calibration of induction frequency by machine’s software (calibration maximizes method’s efficiency)

- 90° handgrip for inductors with remote control (operator can control machine directly from the inductor)

- Length of cable of heating head: 8 meters (on request cables can be supplied with length of 15 meters)

- Lenght of power supply cable: 8 meters (on request cables can be supplied with length of 15 meters)

External characteristics

- Machine is on 4 wheels and it can be lifted by crane or moved by forklift

- Main dimensions: 700 x 980 x 1100H mm. Extremly compact and light. No external parts !

- Flat working table atop

- Provided with box including small tools and consumables

- Machine weight: 180 Kg (included cable, heating head and water)

- Support for head and inductor’s fender on machine

- Machine is delivered in a special wooden box; total weight about: 240 kg)

Documents / Downloads

Video