SKF Vibracon Chocks

SKF Vibracon Chocks

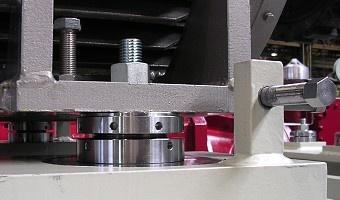

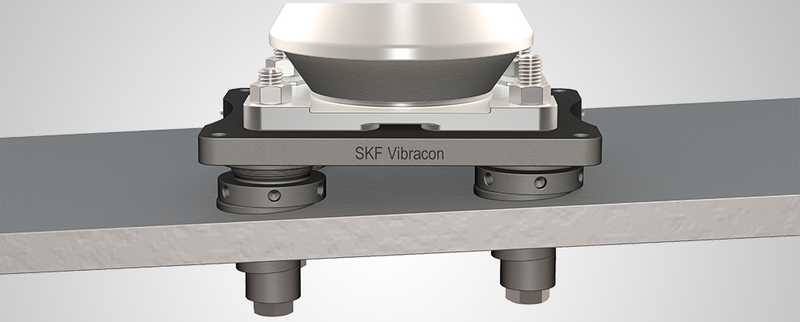

SKF Vibracon chocks are our permanent, strong and re-usable machinery mounting chocks for all types of rotating or critically aligned machinery. Using SKF Vibracon chocks is the most economical way to establish a perfect mounting plane. As SKF Vibracon mounts are mechanically stiff chocks, accurate mounting is made simple and quick. nauwkeurige montage eenvoudig en snel uitgevoerd.

Advantages:

- Absence of curing time

- Eliminates the trial and error alignment process

- Adjustability during the life cycle of the machinery

SKF Vibracon chocks are a fast and safe way to chock your new-builds as well as repairs. This is supported by a type approval from all major classification societies, as well as approval of use by the US Navy.

The Original

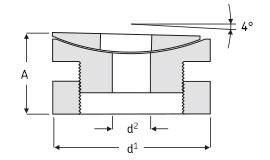

SKF Vibracon chocks are machinery mounting chocks that are easily and accurately adjusted. The chocks accommodate up to a 4° angular difference between machine and the mounting base without expensive machining of the base or extra work of installing epoxy resin chocks. The self levelling capability combined with the height adjustment feature eliminates the possibility of a soft foot in the production line.

The Low Profile

The Low Profile chocks offer an economic solution for repair projects or fixed design systems where expensive milled chocks, shims or epoxy resins were applied. The SKF Vibracon Low Profile configuration addresses those applications where the chock height between the foundation and component has been established by the previous design. A variety of adjustment tools for confined installation spaces are available.

Specialized Solutions

Vibracons are not limited to the two types mentioned. Many additional configuration and material options are available and routinely deployed to solve mounting problems.

Typical solutions are:

- Extended SKF Vibracon

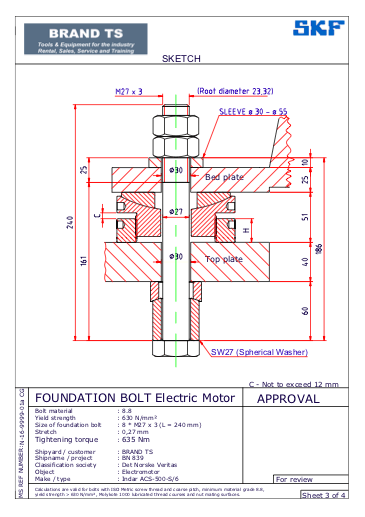

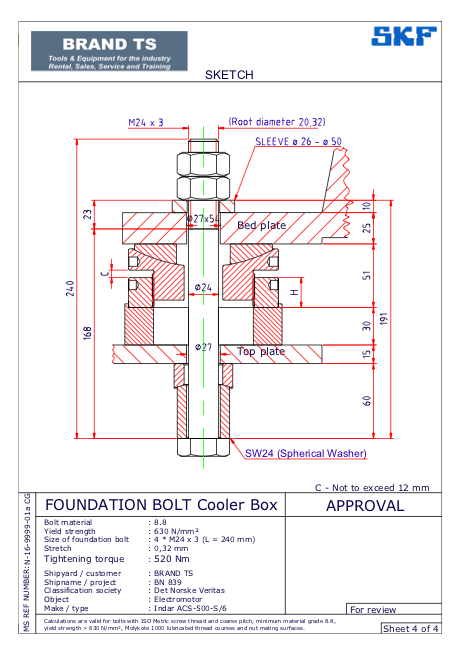

- Spherical Washer

- Slotted elements

- Shock hardened SKF Vibracon

- Additional bottom ring

- Stopper

It is advisable to order Spherical Washers to accompany your SKF Vibracons in order to optimize the mounting of your machinery.

Mounting Kit

For your convenience, SKF Solution Factory - Marine Services offers you a SKF Vibracon mounting kit . This is a complete set of high quality components which allow accurate and fast installation of propulsion units and auxiliary equipment and can contain: SKF Vibracon chocks, foundation bolts, fitting bolts, nuts, Spherical Washers and plan approval certificate of the classification society of your choice.

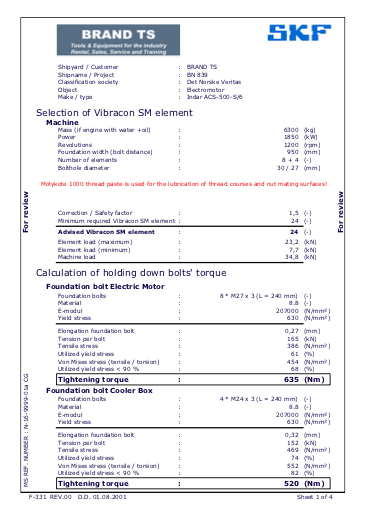

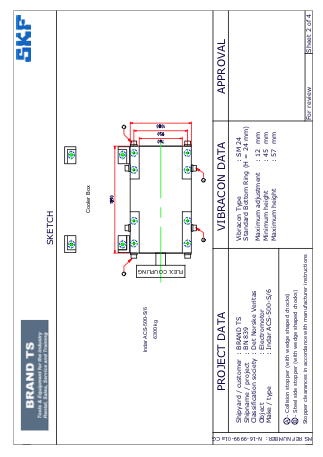

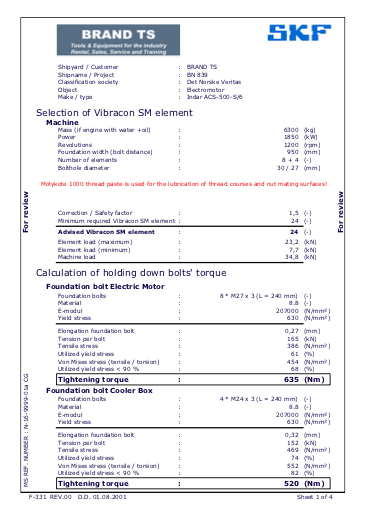

Chocking Proposal

To find out which SKF Vibracon solution is the best for your particular situation, we can create a chocking proposal free of charge and free of any further engagement. The proposal process looks like this:

- Step one: Download an empty data sheets asking for the required information.

- Step two: Send us the completed data sheet.

- Step three: We provide you with the chocking proposal including the recommended amount of chocks and the recommended bolts as well as their tightening torque.

- Step four: Class approval from the classification society of your choice is arranged for you.

Dimensions

|

||||

| Designation | A min | A max | d1 | d2 |

| CS series | ||||

| SM 12 -CS | 30 | 38 | 60 | 17 |

| SM 16 -CS | 35 | 45 | 80 | 21 |

| SM 20 -CS | 40 | 50 | 100 | 25 |

| SM 24 -CS | 45 | 57 | 120 | 31 |

| SM 30 -CS | 50 | 62 | 140 | 37 |

| SM 36 -CS | 55 | 67 | 160 | 44 |

| SM 42 -CS | 60 | 72 | 190 | 50 |

| SM 48 -CS | 70 | 85 | 220 | 60 |

| SM 56 -CS | 75 | 90 | 230 | 66 |

| SM 64 -CS | 80 | 95 | 250 | 74 |

| SS series | ||||

| SM 12 -SS | 30 | 38 | 60 | 17 |

| SM 16 -SS | 35 | 45 | 80 | 21 |

| SM 20 -SS | 40 | 50 | 100 | 25 |

| SM 24 -SS | 45 | 57 | 120 | 31 |

| SM 30 -SS | 50 | 62 | 140 | 37 |

| SM 36 -SS | 55 | 67 | 160 | 44 |

| SM 42 -SS | 60 | 72 | 190 | 50 |

| SM 48 -SS | 70 | 85 | 220 | 60 |

| SM 56 -SS | 75 | 90 | 230 | 66 |

| SM 64 -SS | 80 | 95 | 250 | 74 |

| CSTR series | ||||

| SM 12 -CSTR | 30 | 38 | 60 | 17 |

| SM 16 -CSTR | 35 | 45 | 80 | 21 |

| SM 20 -CSTR | 40 | 50 | 100 | 25 |

| SM 24 -CSTR | 45 | 57 | 120 | 31 |

| SM 30 -CSTR | 50 | 62 | 140 | 37 |

| SM 36 -CSTR | 55 | 67 | 160 | 44 |

| SM 42 -CSTR | 60 | 72 | 190 | 50 |

| SM 48 -CSTR | 70 | 85 | 220 | 60 |

| SM 56 -CSTR | 75 | 90 | 230 | 66 |

| SM 64 -CSTR | 80 | 95 | 250 | 74 |

| ASTR series | ||||

| SM 16 LP-ASTR | 20 | 30 | 80 | 21 |

| SM 20 LP-ASTR | 20 | 30 | 100 | 25 |

| SM 24 LP-ASTR | 20 | 30 | 120 | 31 |

| SM 30 LP-ASTR | 20 | 30 | 140 | 37 |

| SM 36 LP-ASTR | 30 | 40 | 160 | 44 |

| SM 42 LP-ASTR | 35 | 45 | 190 | 50 |